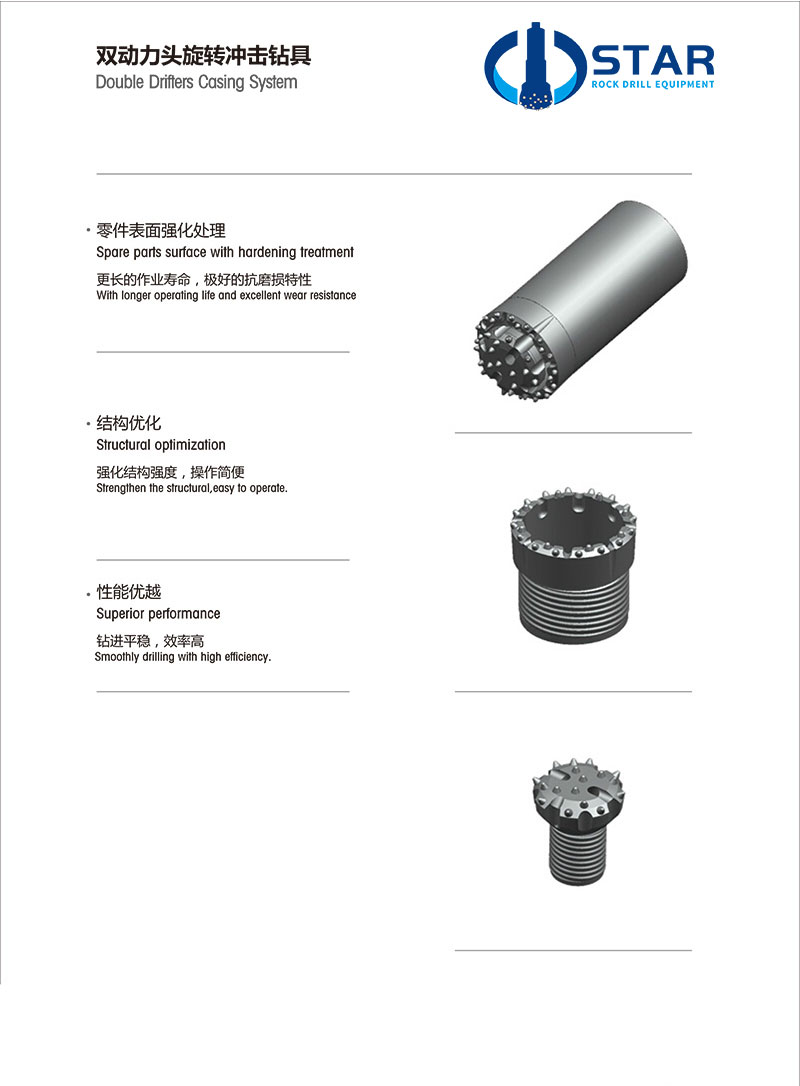

Double Drifter Casing System

Double head rotary percussive casing system utilizes a rotary head to drive the outer casing equipped with a tungsten carbide crown and a hydraulic drifter (top hammer) to drive the inner drill string equipped with a percussive drill bit. This is an excellent method for drilling straight holes in varying ground conditions. The water and compressed air can be both provided as power.

1.It is application on Drilling geothermal wells, side slope anchoring, cofferdam grouting ects.

2.the Double Head Casing Drilling Systems add flexibility to drilling in varying conditions.

During drilling, water or compressed air are used as medium, and the discharge head makes the casing tube and drill rod rotate and penetrate.

In addition to the benefits of increased flushing control, the inner and outer strings are able to be separately controlled, which greatly increases control over drilling operation.

For deeper borehole applications the double casing drilling tools allows for a dual string drilling system with internal flushing, which maximizes the precision to target.

3.Connect the crown opener bit with the casing tube, one of drifter of the drill rig impacts the external casing tube forward until finish the completion of the first casing tube

4.The outer thread bit is connecting with the drilling rod, the other drifter of the rig impacts drill rod forward inside the outer casing tube,

until finish the completion of the first drill rod.

5.Two drifters of rigs impacts casing tube and drilling bits and rods forward down separately, until external casing tube is reached the desired depth.

6.No need to add any casing tube in bedrock, only the drill bit with the rod to keep drilling down until reach the desire depth.

Categories

Contact Us

- +86-15910895290

- +86-371 8891 6559

- +86-15910895290

- info@starockdrill.com

- +86-15910895290