Symmetric Bit with casing shoe

Stable and reliable working performance

Full face head design for faster penetration and straighter hole

Less torque is required than eccentric drilling

Can drill in vertical, horizontal or any direction

Minimize disruption to the drilled hole

Effective cuttings removal

Unlocking-relocking easily

Easy to operate and system security

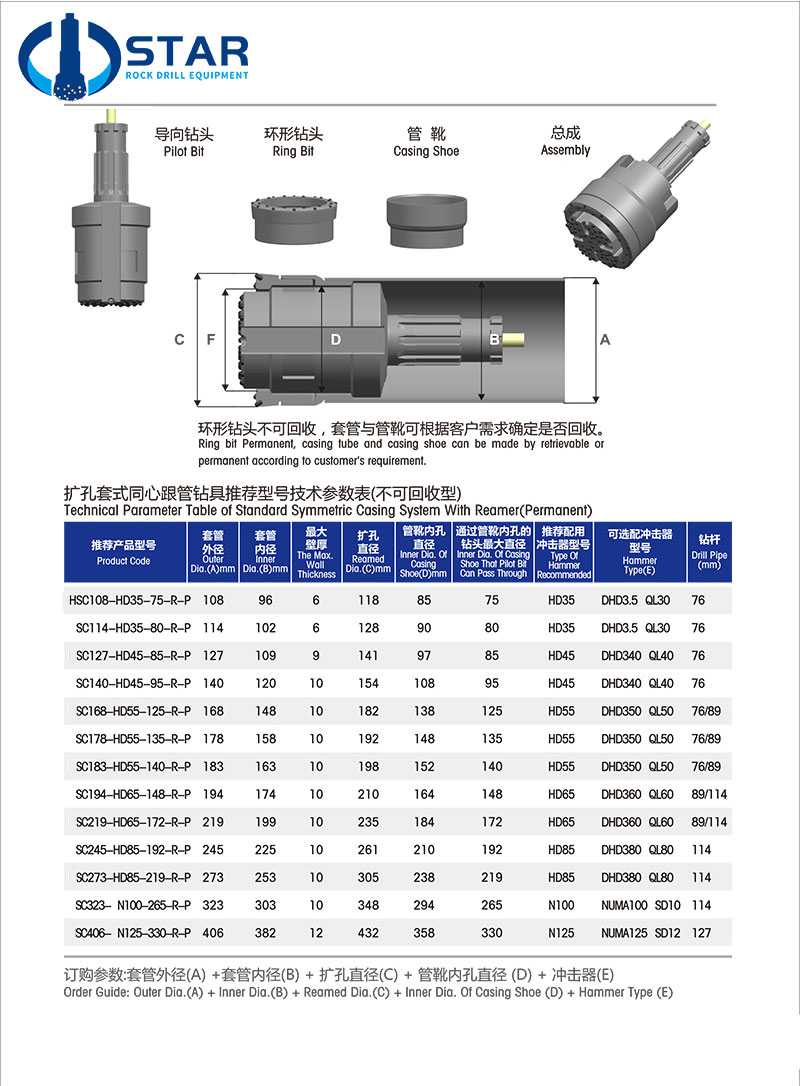

Varied ring bit diameters to suit different casing requirement

The less vibration of drill rig

Symmetric Bit with casing shoe

It is suitable for cobblestone and fracture formation, water wells, geothermal wells , micro-pile, medium and mini grouting hole drilling

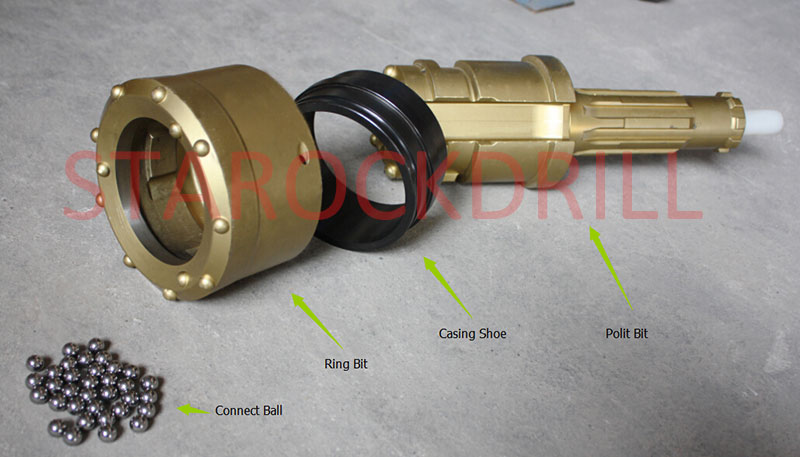

1. Ring bit and casing shoe assembly is welded on casing before drilling, and then lock the pilot bit and ring bit and casing shoe together,

the pilot bit shoulder mesh with casing shoe.

2. The percussive energy is transferred to the pilot and ring bits to crush rock, Part of impact energy leads the casing move forward.

3. After completion of drilling, the drill string with pilot bit is retrieved by a slight reverse rotation to unlock the bayonet coupling,

then the ring bit stays in the hole. When the hole is finished grouting, to pull up casing and ring bits together.

To continue drilling with conventional drilling tools in the bedrock.

Categories

Contact Us

- +86-15910895290

- +86-371 8891 6559

- +86-15910895290

- info@starockdrill.com

- +86-15910895290