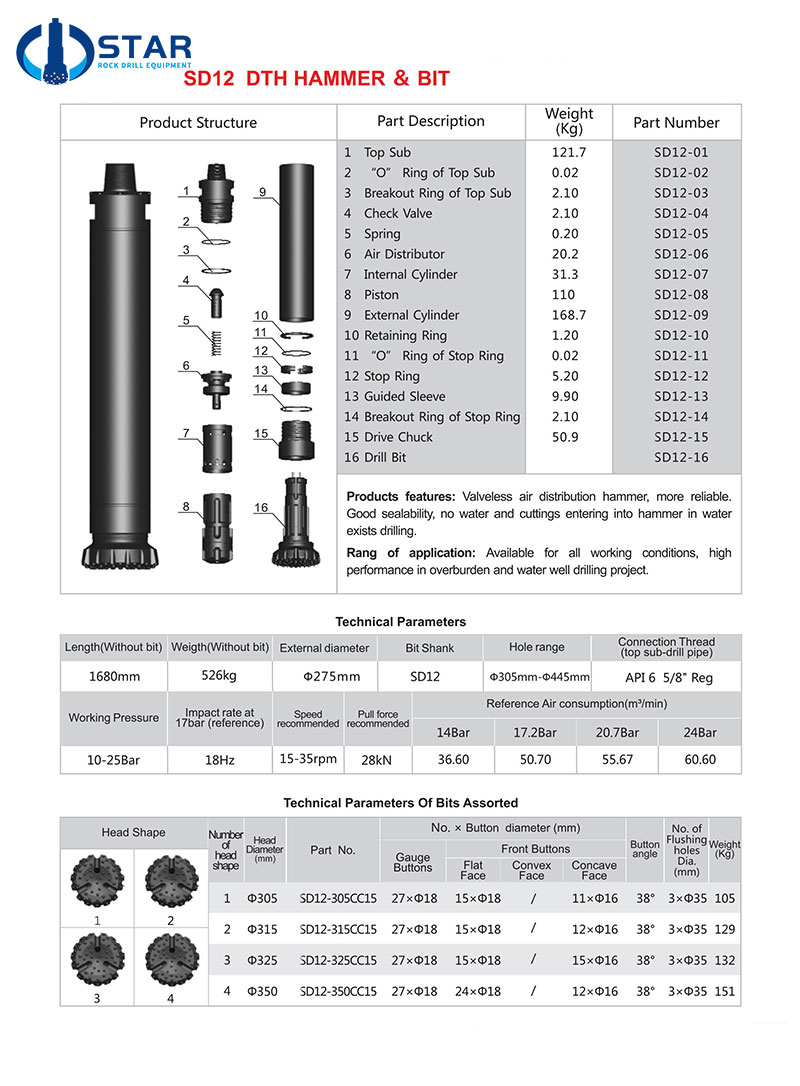

SD12 DTH HAMMER

1.Heat treated piston and internal cylinder guiding system is reasonably structured to achieve the highest efficiency and the largest impacting power.The penetration speed is 10%-30% faster than other products of the

same type.

2.Fine CNC machining tolerance and specifications coupled with

quality assembly lead to great reliability and performance.

3.Hammer front structure design: when pulling out the hammer,the last impact of the piston would fall on the step of piston case,ensuring the safety of the driver sub splines and the retainer ring.

4.Save Lubrication Oil

5.East operation and fix

6.Longer working life

DTH(Down the Hole) hammer is used for drilling holes through a wide range of rock types, the variety of which continues to extend well beyond the original conception of early blast hole drilling.

Down-the-Hole refers to where the hammer action occurs when compared to drifter hammers, which hammer on top of the drill string. The DTH hammer piston always makes direct contact with the drill bit and there is generally no loss of transmitted energy as the hammer drills deeper, as is the case with drifter (top hammer) rigs.

starockdrill hammers are flexible, and designed to work with various industry-standard shank designs and a wide range of standard size hammers. Whatever your application, STAROCKDRILL has the solution to match your requirements.

STAROCKDRILL’S DTH hammers mainly be produced with shank type of DHD, QL, NUMA, COP, Mission, SD, BR, CIR,TD.40 MACH44 and STR series, Diameter ranging from 2” to 8” for mining and quarrying, and 6” to 32” for water-well drilling, oil-well drilling and foundation and so on.

How to order?

Hammer shank + Inches

(If you are not knowing the sizes, we can give you suggestions on hammers and bits)

Categories

Contact Us

- +86-15910895290

- +86-371 8891 6559

- +86-15910895290

- info@starockdrill.com

- +86-15910895290