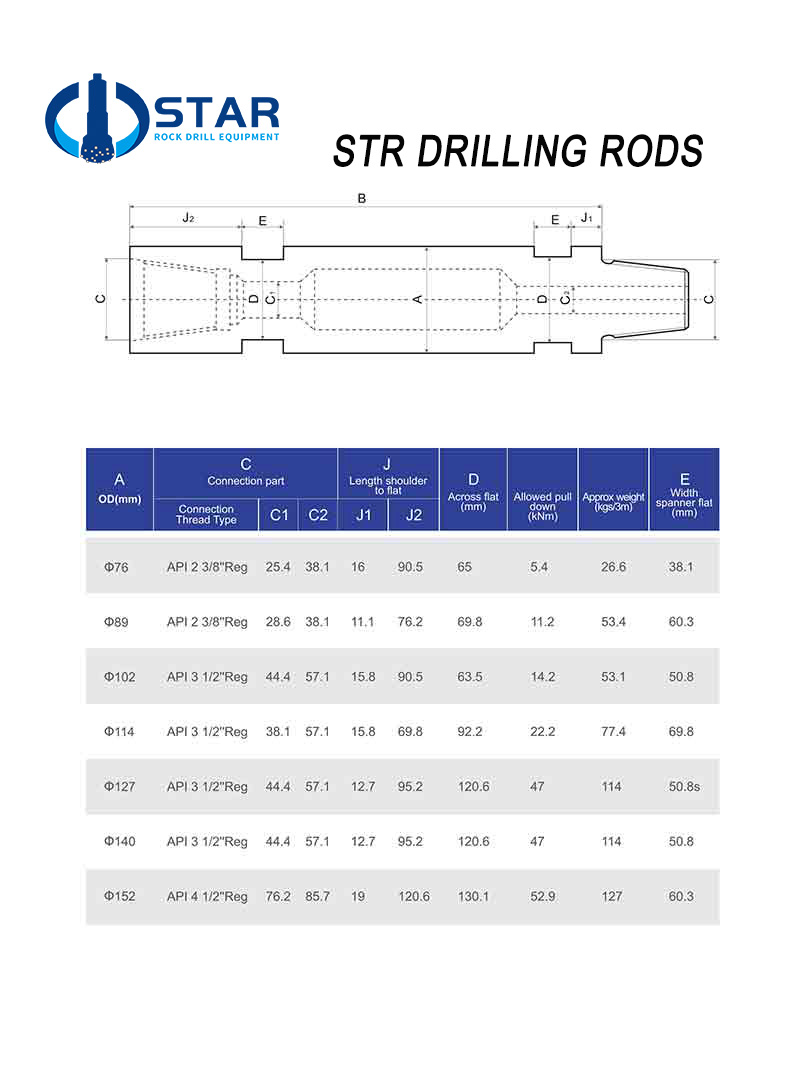

DTH DRILL ROD

1:Nitriding on the thread of rod joint to improve the hardness of thread surface and increase the wear resistance of thread.

2:Using DZ50/R780 as the material of rod body to improve the wear resistance and the strength, 35CrMo materials for thread connect.

3:Adopts the upsetting treatment to reduce the weight of rod while keep the strength of the welds.

Upsetting treatment technology

4.Friction Welding

DTH drill rods (also called as drill tubes or drill pipes) are the mechanism to transmit impact force and rotation torque to DTH hammers and bits,

as well as offer pass for the air flow.

In principle, the lighter the rod is, the better it is for the drilling operation. So a thinner one is always preferable than a thicker one if other parameters were the same.

While in the mean time, the yield strength and the tensile strength must also be taken into accounts,

which means relatively rod wall thickness would be needed to obtain enough strength.

Of course, once the thickness is rigidly requested as thin as possible to minimize the drill string weight,

there is also another method to get optimum drill tubes that using better grade steels.

STAROCKDRILL’S DTH drill rods with several different thickness designs for each diameter, made from different grade steels for selection.

So, in practice of field drilling, under different condition, there may be in need of different kinds of drill rods for particular application.

For example, the thicker ones with general high quality grade steel for drilling hole of average depth, such as blasting holes;

and the thinner ones with better grade steel for drilling hole of very deep, such as drilling for ground thermal.

Moreover, STAROCKDRILL’S DTH drill rods are also well heat-treated, precision manufactured, and friction-welded.

Categories

Contact Us

- +86-15910895290

- +86-371 8891 6559

- +86-15910895290

- info@starockdrill.com

- +86-15910895290