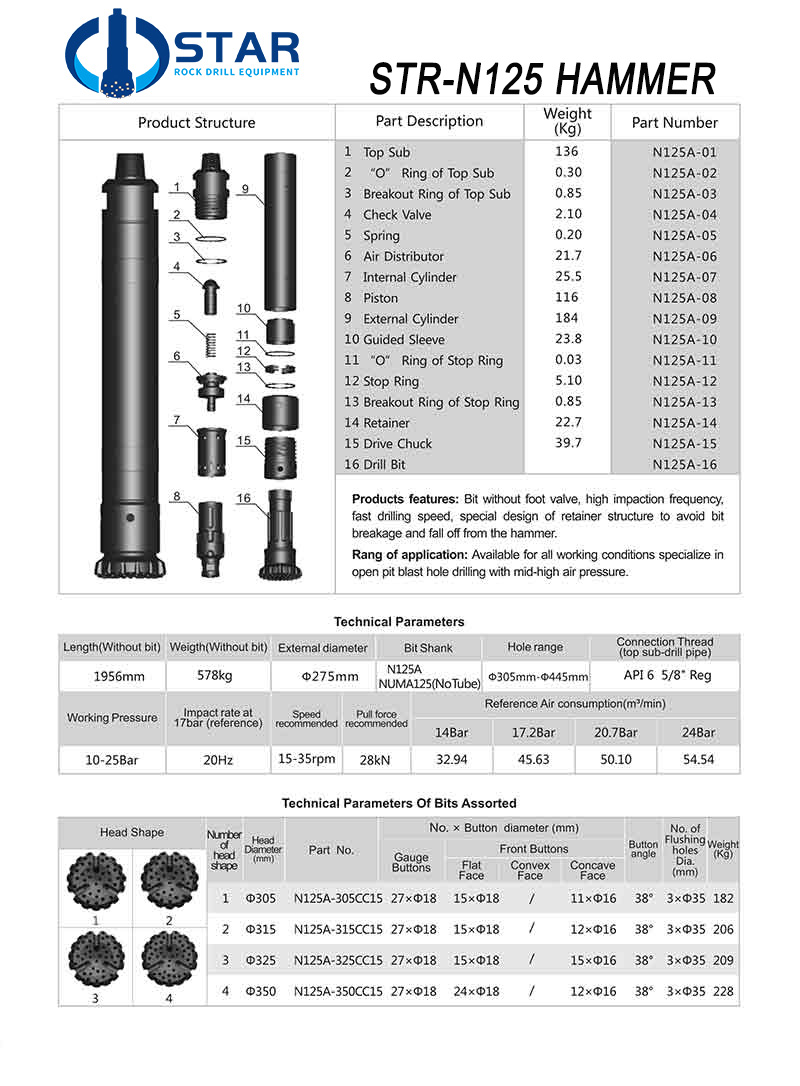

N125 DTH HAMMER

1.The piston has a simple structure and is not easily damaged.

2.Ideal energy transfer, fast drilling speed, low air consumption and low fuel consumption.

3.The parts used are few, the structure is simple, and all parts are hardened, so it has a long working life, few failures and convenient maintenance.

4. The joint and the clamping sleeve are connected with the outer cylinder by threads, which is easy to disassemble.

The N125 hammer adopts rock drilling theory to design the internal structure size of the hammer, so that the hammer can obtain ideal energy transmission,

with large single impact energy, high impact frequency and lower air consumption; Selection of high-quality raw materials and advanced processing technology,

more stable performance, longer life. The domestic advanced heat treatment process is adopted to ensure the good mechanical properties of the hammer.

STAROCKDRILL’S DTH hammers mainly be produced with shank type of DHD, QL, NUMA, COP, Mission, SD, BR, CIR,TD.40 MACH44 and STR series,

Diameter ranging from 2” to 8” for mining and quarrying, and 6” to 32” for water-well drilling, oil-well drilling and foundation and so on.

Advantage:

1.Heat treated piston and internal cylinder guiding system is reasonably structured to achieve the highest efficiency and the largest impacting power.

The penetration speed is 10%-30% faster than other products of the same type.

2.Fine CNC machining tolerance and specifications coupled with

quality assembly lead to great reliability and performance.

3.Hammer front structure design: when pulling out the hammer,the last impact of the piston would fall on the step of piston case,

ensuring the safety of the driver sub splines and the retainer ring.

4.Save Lubrication Oil

5.East operation and fix

6.Longer working life

How to order?

Hammer shank + Inches

(If you are not knowing the sizes, we can give you suggestions on hammers and bits)

Categories

Contact Us

- +86-15910895290

- +86-371 8891 6559

- +86-15910895290

- info@starockdrill.com

- +86-15910895290