News

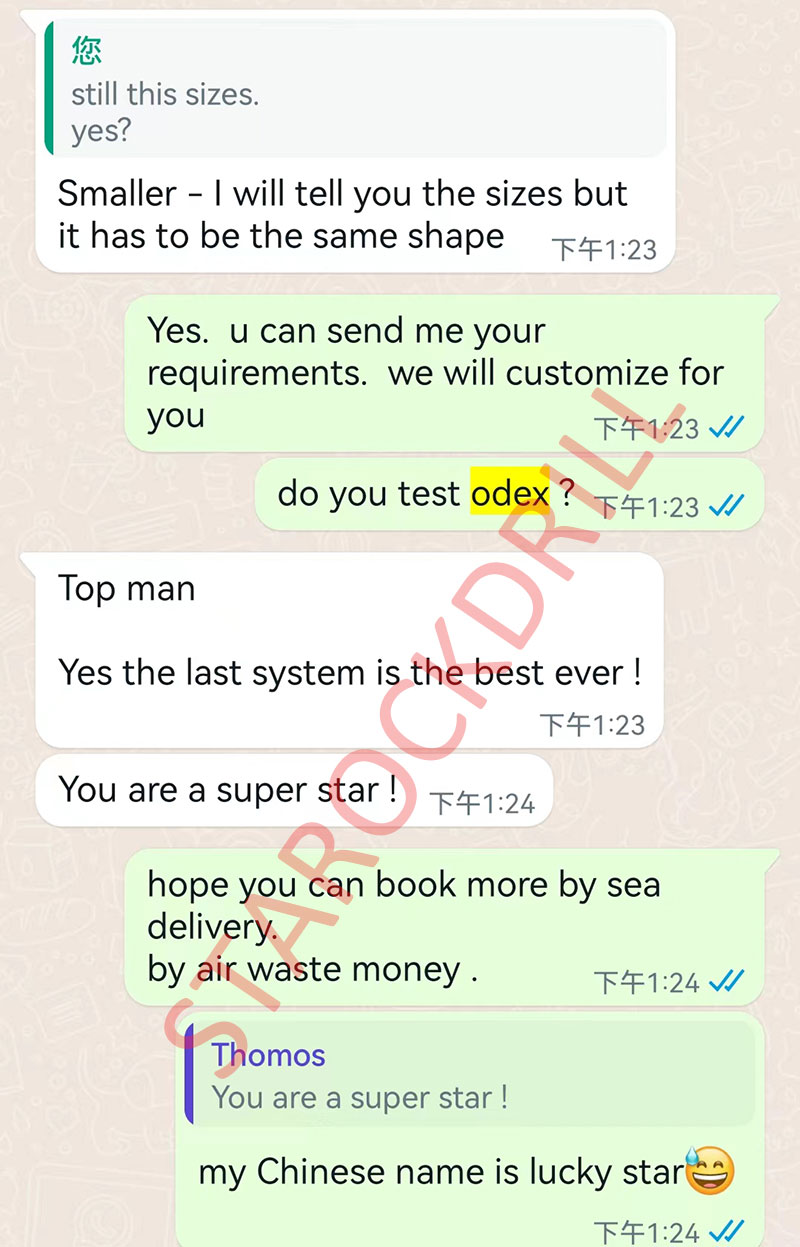

Feedback ODEX BIT FROM CUSTOMER

When a renowned client in the UK focused on water well and geothermal drilling faced challenges with local eccentric casing systems

that failed to meet their drilling speed and depth requirements, including issues like fractures and breakdowns,

they turned to us for a solution. Understanding their drilling needs in formations primarily composed of gravel and sandstone,

and considering their feedback on worn-out drill bit bodies and heavily worn alloy teeth,

we undertook a profound heat treatment process to enhance the durability of our drilling equipment.

Additionally, we incorporated alloy teeth on both sides of the guiding drill bit to minimize wear caused by geological conditions.

The moment our client received our product, they exclaimed it was the best they had ever used and decided to establish a long-term procurement partnership

Categories

Contact Us

- +86-15910895290

- +86-371 8891 6559

- +86-15910895290

- info@starockdrill.com

- +86-15910895290